charcoal briquette production line

charcoal briquette production line

Carbon Powder Molding Production Line

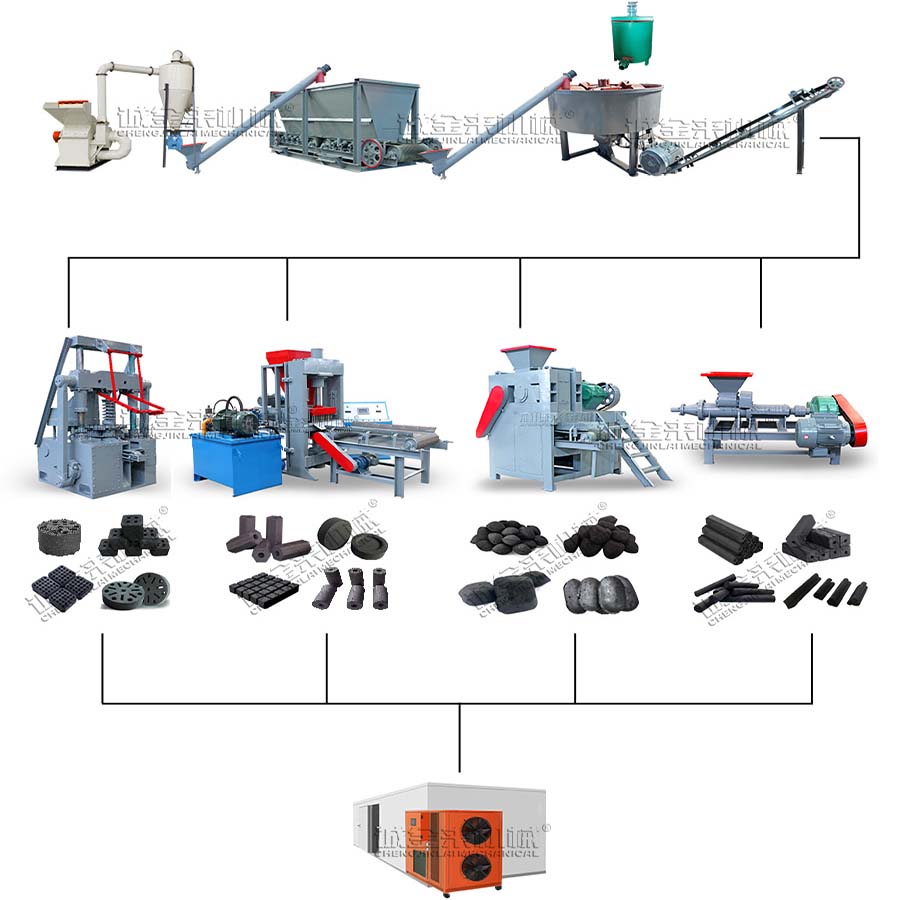

The production process of the carbon powder molding production line is to use a crusher to grind the charcoal into powder, then use a charcoal mixer to mix the charcoal powder with a binder, put starch and water into the binder mixer, and then mix.The last step, according to your needs, use our ball making machine to produce a variety of different shapes of balls.

Production process:Crushing——Mixing——Forming——Drying

Main machine list

The charcoal crusher machine for charcoal is especially suitable for charcoal powder processing, it’s maked up by cutting device,crushing device and fan.

It mainly processing wood charcoal,coconut shell, bamboo charcoal,peanut charcoal, carbonized wood chips or small wood log, etc.The final discharged powder is from 80-100 mesh.

Wheel Mill Mixer is a model that combines wheel milling and mixing, designed according to the advantages of new wheel milling and mixing equipment.

The multi-function wheel mill mixer is a motor V-belt drive instead of rotating the impeller, which fully mixes the medicine and the slurry, increases the reaction time of the medicine, and strengthens the quality of the medicine reaction.

Ball Briquette Press Machine are rollers pressing type. This type of briquette presses can apply higher pressures and thus produce higher density briquettes .

These briquettes can be designed of oval shape, egg shape, pillow shape, square shape etc. This machine is widely used in coal industry and metallurgy industry.

Coal rod machine (also called coal rod extrusion machine) is the use of spiral extrusion principle,the modulated powder coal compressed into a certain strength of the circular (or six prism or square)coal rod molding equipment.

Its working principle is: The motor transmits power to the transmission through the triangle belt,and the output shaft of the transmission transmits power to the propulsion shaft through the floating coupling. The propeller on the propulsion shaft pushes the coal material out through the forming die head,and the high pressure coal rod is produced.

Honeycomb briquette machine takes the coal powder as raw materials, through mixing, pressing and molding the materials into honeycomb or columnar rod shaped briquettes.

It is the multifunctional machine, and we can change the moulds to manufacture different shapes and sizes of briquettes, like cylindrical shape, square shape, rod shape, flower shape and other shapes, which expand the function of the machine greatly.

Hydraulic Charcoal Briquette Making Machine is composed of hydraulic system, PLC system, Host mold, Big feeding port, Mesh belt conveyor.

1). 80-120tons pressure.

2). raw materials can be: Coconut shell charcoal, charcoal powder, coal powder, sawdust charcoal, etc.

3). briquette height can be adjusted. It can customize different shapes.

4). final charcoal briquettes are usually used for BBQ, smoking.

Heat Pump Dryer/Drying Machine takes advantage of the reversed Carnot principle, absorbing the heat from around and sending the heat to the materials which will be dried.

This kind of dryer is mainly composed of heat pump dryer and drying chamber.

This dryer will be controlled by touch screen controller, and the temperature can be adjusted. It has low electric consumption.

Raw Materials & Finished Products

1. Coal/coke/charcoal powder.

a) Size of materials: less than 1mm, should be controlled between 30-40%; between 1-2mm, should be 30-40%; the max size should be no bigger than 3mm, with 20%.

b) Moisture of material: should be in 8-12%.

c) Not allowed: slad or other massive sundries with high hardness, or the roll and splindle will be damaged.

d) Agglomerant or other additives: should be prepared by users in accordance with coal type and the operating environment.

Factory delivery site

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.