Carbonization production line

Carbonization production line

Production line Introduction

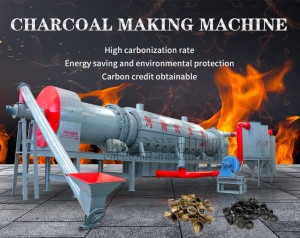

Our Continuous Carbonization Furnace is the new type which can carbonize the sawdust, wood chips, bamboo chips, coconut shell chips, peanut shell etc. It works continuous, and for the first material feeding in the carbonization machine to get the charcoal, it needs about 30 mins. The entire production process does not produce harmful gases, does not pollute the environment, and is excellent in various carbonization furnaces.

Production process: Crushing——Drying——carbonization

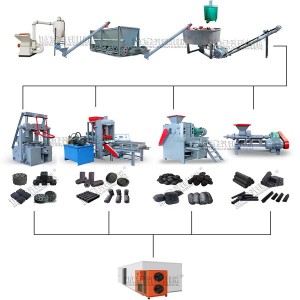

If you want your final product to be pressed into a customized shape, you can use the following production line.

Production process: Crushing——Drying——carbonization——Crushing——Mixing——Forming——Drying

Raw Materials & Finished Products

What raw materials can be carbonized using this production line?

There are abundant raw materials that can be carbonized,such as sawdust, wood chips, rice husks, coffee shells, olive residue, palm fiber, bagasse, coconut shell fragments, palm shells, hazelnut shells, various fruit shells, fruit cores, etc.

If the raw materials are large, we need to use a crusher to crush them into sawdust. In addition, if the sawdust is too humid, we need to use a sawdust dryer to dry it to reduce its moisture content.

Main machine list

Drum type continuous carbonization furnace, also referred to as single barrel carbonization furnace, is the wood chips, rice husk, peanut shell ,plant straw, hart and other lignin materials containing carbon are first crushed by hammer mill(particle size requirements are below 5mm), and then dried by dryer or natural sun dry (moisture requirements are below 20). Then through the drum carbonization furnace drying distillation, carbonization, cooling and other processes, so that the loose raw materials into the required charcoal process.

Compared with the traditional carbonization furnace, it is easier to operate, it has higher thermal efficiency and lower energy consumption.

The continuous carbonization furnace is mainly used for the carbonization of biomass materials. The equipment is still using the principle of gasification carbonization and adopts advanced smoke-free environmental carbonization process:The whole set of equipment consists of gasification system (liquefied gas gasification machine), purification system (spray tower, cyclone dust removal, water cooling, oil water separator, fine filter) and control system (control cabinet). The whole carbonization process is automated production, automated operation.

Factory delivery site

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.