Charcoal Extruder Machine

Charcoal Extruder Machine

CHARCOAL EXTRUDER MACHINE

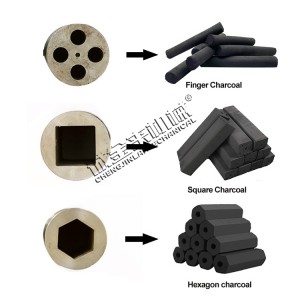

The machine for briquette can extrude different powder materials into briquettes, for example charcoal powder, coal powder, etc. It both can produce BBQ charcoal(cylinder shape, hexagonal shape, quadrangular shape) ,shisha hookah charcoal(cubic shape, round strip shape, hexagonal strip shape).

Working Principle of Charcoal Briquette Extruder Machine

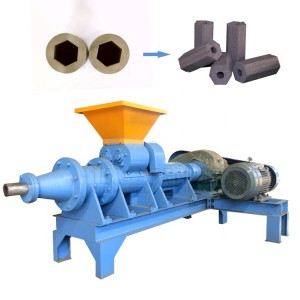

The charcoal extruder machine adopts the principle of screw extrusion to compress the coal/charcoal powder into shaped briquettes. After the charcoal powder is poured into the feeding hopper, it is propelling forward to the discharging hole of the briquette machine by the screw. From the screw chamber to the mold, space is becoming smaller. Under the tremendous pressure, charcoal passes through the molds and finally form into certain shapes.

The main structure of the coal stick machine is composed of a motor, a reducer, a screw propeller shaft, a mold, and the final cutter.

We provide customers with a large number of different molds to choose from, and we can also customize them according to customer needs.

This machine has a compact design, including the electric motor, reduction box, feeding hopper, screw propelling part, discharging hole, machine base, etc.

Usage

1.Pressing charcoal dust into solid or hollow cylinder, square, hexagon shape briquette for barbecue.

2.Different diameter of final briquettes meets with different market requirement.

3.It suitable for different types of carbon powder;no matter forest wastes ot agriculture waste carbon dust.

Different cutting methods

1. Pneumatic cutting device

This kind of pneumatic cutting machine is generally equipped at the exit of the charcoal briquette machine and equipped with an induction device. When the coal rod reaches a certain length, it will automatically cut.

2. Cubic charcoal cutting machine

This cubic cutting device is used to cut cubic coal. The cut coal rods pass through this machine to become coal blocks of uniform shape and size.

3. CNC cutting device

This is our latest coal cutting machine. It adopts an intelligent control system, the cutting length of coal rods can be adjusted freely and can be used to cut coal rods of various shapes.

Raw Materials & Finished Products

Almost all kinds of biomass material are available to this machine: sawdust, shavings, wood waste, branches, rice husks, peanut shells, bagasse, vinasse, cotton rods, corn rods, wheat straw, rice straw and other crops. This And the raw material is first to be carbonized and then to pressed into carbon rods.

finished product ↓↓↓

Besides the charcoal and coal, this extruding machine can also produce briquettes from coke, sludge, olive pomace, cow dung, etc. For making good quality briquettes, charcoal powder size must be less than 3mm, and moisture around 20%. To meet the requirements of different customers, mold shapes can be hexagonal, square, circular, etc. Moreover, customers can choose to produce hollow or solid briquettes and the briquette’s diameter range is 3-50mm.

Machine Parameters

|

Model

|

CM140

|

CM160

|

CM180

|

|

Capacity

|

1-1.5t/h

|

1.5-2t/h

|

2-3t/h

|

|

Power

|

15kw

|

22kw

|

22kw-30kw

|

|

Feeding size

|

≤5mm

|

≤5mm

|

≤5mm

|

|

Moisture content

|

25%-35%

|

25%-35%

|

25%-35%

|

How to Use?

1. If the raw material is sawdust or rice husk or coconut shell.Use carbonization furnace to carbonize raw material into charcoal.

2. The seond step:Use crusher to grind charcoal into powder.

3. Then use the Charcoal mixer to mix the charcoal powder with binder and water.

4. Use charcoal extruder machine to produce many different shapes briqette base on own need.

5. Dry the final products by dryer or naturally

Factory delivery site

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.