Charcoal Machine Production Line

Charcoal Machine Production Line

SAWDUST BRIQUETTE MACHINE

The machine can produce hollow hexagonal or quadrangular cylinder briquettes with different diameters from agro-forestry wastes, such as sawdust, wood chips, branches, crop stalks, sugarcane residue, coffee husk, paddy straw, sunflower stalk, cotton stalks, bamboo dust, palm husk, soybeans husk, tea waste, etc.

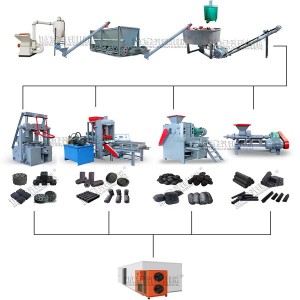

Charcoal Machine Production Line

Production Process : Crushing --- Drying --- Press briquette --- Carbonizing briquette to charcoal

Main machine list

The crusher is particularly suitable for crushing raw materials and consists of a cutting device, a crushing device and a fan.

It mainly processes various wood wastes, such as logs, branches, old furniture, furniture scraps, sawdust, wood chips, etc., and various agricultural wastes, such as rice husks, peanut shells, straw, corn cobs, coffee shells, palm fibers, etc.

This charcoal briquette machine can be used to mold the sawdust, and the molded sawdust sticks will be carbonized by the carbonization furnace to get the sawdust charcoal. The machine can realize the molding of many kinds of biomass, such as wood chips, rice husk and so on. After the molded sticks being carbonized by the carbonization furnace, the corresponding charcoal can be obtained. If you have other raw materials you can contact us, we will give you the best plan to get the finished product you want.

Carbonization furnace are special used cart entry and exit raw material and the advanced hot gas dry carbonization process technology, using a unique carbonization flue gas. Back Burning Technology, make full use of the flue gas produced by carbonization process, meet the thermal needs of carbonization furnace itself, greatly increase the carbonization rate, the carbonization rate increased from 80% to more than 95%, and easy to operate, safety and environmental protection, high production efficiency, can save a lot of energy, is the ideal equipment for carbonizing the long rod type biomass material.

Raw Materials & Finished Products

Almost all the biomass are suitable for charcoal machine, such as peanut shell, coconut shell, wood, biomass, some crops, bamboo, waste wood, branches, trunks, logs, bark, stumps, roots, wooden pallet, sawdust, shavings, wood chips, fruit wood, rice husk, corncob, peanut shell, furfural residue, palm shell, semi-coke and etc.

Then put the compressed rods into the horizontal carbonization furnace and seal the furnace. The carbonization furnace will preheat, dry, anaerobically carbonize the raw materials, and finally cool and produce carbon.

Factory delivery site

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.