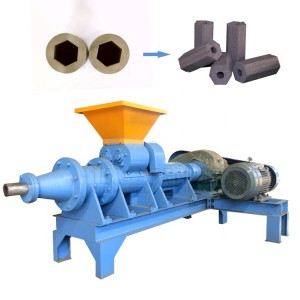

Coal rod machine

Coal rod machine

Product description

Coal rod machine (also called coal rod extrusion machine) is the use of spiral extrusion principle,the modulated powder coal compressed into a certain strength of the circular (or six prism or square)coal rod molding equipment.Widely used in pulverized coal,coal foam,coal gangue,coking coal, brown coal,anthracite,iron powder,aluminum powder and other raw materials molding,mold can be customized according to customer needs.The equipment has the advantages of small size,strong bearing capacity,low production cost,economic benefits and durable.

Process flow

First of all, coal, charcoal and other large materials will be crushed to less than 5mm by multi-functional pulverizer, and the crushed powder will be mixed with appropriate binder and water by wheel mixer, and then formed into rods by coal rod machine, and finally dried by drying machine or naturally dried in the sun.

Raw Materials & Finished Products

Raw Materials

Coal powder, coal foam, coal gangue, coking coal, lignite, anthracite, iron powder, aluminum powder and other raw materials.

Finished Products

BBQ charcoal: pentagon, pentafoliate, hexagonal shape, round shape, quadrangular shape, with hole in center or not, etc.

Shisha hookah charcoal: square shape, hexagon shape, triangle shape, Pentagon shape, cubic, round, cubic shape, round shape, etc.

Length: we can also install auto-cutter for you at the machine outlet, the finished product length can be adjusted. You also can cut it by manual.

Machine Parameters

Below are the parameters of our machines, for different raw material machine solutions, please contact us to know your raw material and we will customize it for you.

|

Model |

Power(kw) |

Capacity(t/h) |

Dimension(m) |

Weight(kg) |

|

140 |

15 |

0.8-1.0 |

1.9×1.1×1.17 |

650 |

|

160 |

22 |

1.2-1.5 |

2.2×1.3×1.4 |

850 |

|

180 |

22-30 |

1.0-1.2 |

2.2×1.3×1.4 |

1050 |

Factory delivery site

With our professional transportation team and reasonable transportation methods, we can make sure the goods are delivered to the destination on time. During transportation, we will surround the machine with thickened export wooden crates to protect the machine from impact and friction. So you don't have to worry about the damage of the machine during transportation.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.