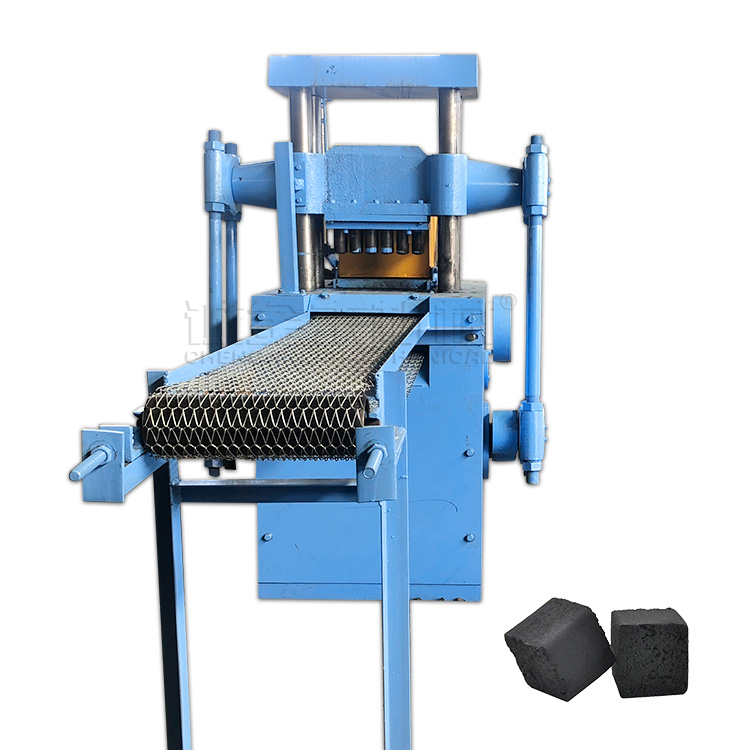

Cube Shisha Charcoal Machine

Cube Shisha Charcoal Machine

CUBIC SHISHA BRIQUETTE CHARCOAL MACHINE

The press machine produced by Chengjinlai Machinery can be used as hookah carbon tablet machine, charcoal powder tablet machine, animal salt block tablet machine, dry powder tablet machine, mineral powder tablet machine, powder tablet machine, food tablet machine Machine, pharmaceutical tablet press, fertilizer tablet press, feed tablet press and other large and medium-sized tablet press equipment.

This series of tablet presses are suitable for all kinds of dry and wet powdery granular materials, such as hookah carbon,crystal carbon, silicon carbide, carbon powder, coal powder, coking coal, smoked eggs, greenhouse smoke agent, solid wax, urea,fertilizer, feed, traditional chinese medicine slag, western medicine powder, ammonium chloride, furfural slag, rare earth, bauxite, oxide scale, lime powder, dust, bleaching powder, iron powder, etc. are pressed into forming.

Usage

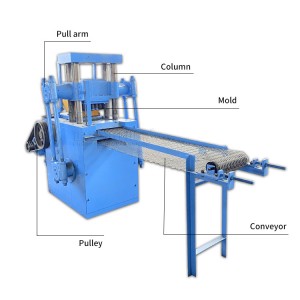

1. This machine is particulary suitable for pressing of large diameter, large filling quantity of tablets.

2. Specially designed forced feeder, can compress charcoal pure powder material with light weight, small density.

3. Specially designed auxiliary equipment, can realize automatic feeding, automatic discharging tablets.

4. Humanized design, the machine is easier to clean and maintain.

5. Special installation structure, make the down rail guide and pressure wheel replacement and maintain convenient.

6. Drive system is airtight in the worm box at the bottom of the main body, is a completely seperated and independent part, neither pollution each other, and make the drive system get sufficient lubrication, reducing noise and wearing.

Raw Materials & Finished Products

1. Applicable raw material: charcoal powder of biomass material such as: sawdust, wood shavings, wood wastes, branches, rice husk, peanut shell, coconut shell, begasse, sediment, cotton stem, corn stalk, corn cob, etc. After carbonization, the charcoal can be used as raw material.

2. The inlet particle size of raw material: it must be less than 3mm.

3. You must add a certain proportion of liquid binder of some kinds of materials for shaping easily, besides, the binder can also increase the hardness of material, and make the briquettes easily burning.

4. The moisture of materials for briquetting must be moderate, the water content should be 12-15%.

Machine Parameters

|

Model

|

CJL9

|

CJL12

|

|

Number of molds(pair)

|

9

|

12

|

|

Finished product diameter

|

15-50mm

|

15-50mm

|

|

Yield

|

9 tablets/time

|

12tablets/time

|

|

power

|

11kw

|

15kw

|

|

pressure

|

150kn

|

250kn

|

How to Use?

1. If you raw material is sawdust or rice husk or coconut shell.Use our carbonization stove to carbonize your raw material into charcoal.

2. The seond step:Use crusher to grind charcoal into powder.

3. Then use the Charcoal mixer to mix the charcoal powder with binder.

4. Put the starch and water into binder mixer , then mix them.

5. The final step:use our briquette machine to produce many different shapes briqette base on you need.

Factory delivery site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.