Honeycomb Briquettes Machine

Honeycomb Briquettes Machine

HONEYCOMB CHARCOAL BRIQUETTES MACHINE

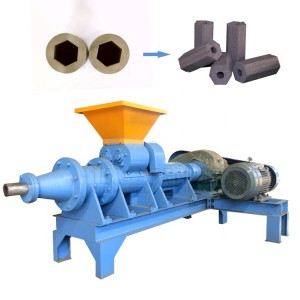

The Honey Comb Charcoal Briquettes Machine structure and principle is simple, divided into the body, rotation, feeding, punching, conveying five parts. All parts cooperate with each other, and the operation is coordinated and smooth. we can change the moulds to manufacture different shapes and sizes of briquettes, like cylindrical shape, square shape, rod shape, flower shape and other shapes, which expand the function of the machine greatly.

Main advantages of coal and charcoal Briquette Making Machine:

1. With different types, we have 140, 160, 180, 220, 260, 300, etc, several different modes to provide you different capacity according to your needs.

2. Applicable raw materials: such as coal powder, coal dust, charcoal powder, coal ash, coal gangue, middlings, brown coal, breeze, furnance slag, coke powder, etc.

3. The moulds are adjustable, one machine can with several different types of moulds, and the change of moulds are very easy to operate.Even you can have your own thoughts, we can manufacture the ideal moulds for you.

The outlet briquettes and shapes of honeycomb charcoal briquette machine:

1. Shape: the shapes of honeycomb coal and charcoal briquette machine can be round, cylinder, square, rectangle, polygon, hexagon, sector, etc various, or you can have your own ideal shapes, we can help you make it as your needs.

2. Size: the final size is according to the shape and the machine mould, also you can decide it under certain range.

3. Feature: the outlet briquettes with the advantages of high density, easy fire, long burning time, and non-toxic, smokeless, etc.

Machine Parameters

|

Model

|

140

|

160

|

220

|

260

|

|

power(KW)

|

7.5

|

7.5

|

11

|

15

|

|

Number of work(n/min)

|

32-45

|

32-45

|

20-28

|

20-28

|

|

Output(T)

|

0.8-1.2

|

1-1.5

|

2-3

|

3-4

|

|

Finished product diameter(mm)

|

140

|

160

|

220

|

260

|

|

Finished product height(mm)

|

30-100

|

30-100

|

30-140

|

30-140

|

|

Equipment size(mm)

|

1350 * 1200 * 1750

|

1550 * 1400 * 1900

|

1950 * 1650 * 2050

|

2050 * 1650 * 2250

|

|

Weight(kg)

|

1500

|

2200

|

3000

|

4300

|

How to Use?

1. If you raw material is sawdust or rice husk or coconut shell.Use our carbonization stove to carbonize your raw material into charcoal.

2. The seond step:Use crusher to grind charcoal into powder.

3. Then use the Charcoal mixer to mix the charcoal powder with binder.

4. Put the starch and water into binder mixer , then mix them.

5. The final step:use our briquette machine to produce many different shapes briqette base on you need.

Factory delivery site

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.