Peanut shell charcoal machine

Peanut shell charcoal machine

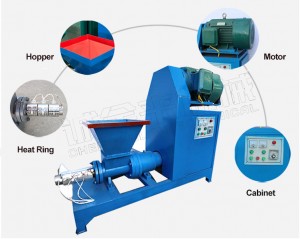

SAWDUST BRIQUETTE MACHINE

The machine can produce hollow hexagonal or quadrangular cylinder briquettes with different diameters from agro-forestry wastes, such as sawdust, wood chips, branches, crop stalks, sugarcane residue, coffee husk, paddy straw, sunflower stalk, cotton stalks, bamboo dust, palm husk, soybeans husk, tea waste, etc.

Working Principle of Sawdust Briquette Machine

The Machine is the primary equipment for charcoal product molding machine, it could making bamboo, straw, wood, nut shell and other raw material, the final product is briquettes with central hole, by the high temperature, and high pressure.

The motor uses a high-quality motor with a full copper core, and the mold is made of chromium-manganese alloy, which has good high-temperature resistance and oxidation resistance.

The hopper adopts a large opening design, which is convenient for feeding and can also make the feeding more uniform. There are a variety of models of molds from the discharge port, and they can also be customized according to customer needs.

The discharge port is equipped with a broken rod rack, which can control the length of the formed biomass charcoal between 10-15cm.

Raw Materials & Finished Products

Almost all the biomass are suitable for charcoal machine, such as peanut shell, coconut shell, wood, biomass, some crops, bamboo, waste wood, branches, trunks, logs, bark, stumps, roots, wooden pallet, sawdust, shavings, wood chips, fruit wood, rice husk, corncob, peanut shell, furfural residue, palm shell, semi-coke and etc.

Machine Parameters

|

Model

|

Productivity

(kg/h)

|

Motor power

(KW)

|

Weight

(kg)

|

Out size

(mm)

|

|

50

|

400-500

|

18.5

|

800

|

1800*500*1700

|

|

80

|

500-600

|

22

|

900

|

1800*500*1700

|

Production Line

Production Line Ⅰ : Crushing --- Drying --- Press briquette --- Carbonizing briquette to charcoal

Factory delivery site

Customer site

We are a professional manufacturer of charcoal machine equipment. We provide customers with production lines and various accessories. Such as trolley, induced draft fan, burner, high-voltage electrostatic system, etc. Therefore, we can customize different sizes of equipment.

If you call or email us now to tell us your specific needs, we will develop solutions for you in a timely manner.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.